Sibom Wheel Loader Material Pushing Devices – Efficient Bulk Handling Solutions

In modern yards, terminals, and industrial facilities, material movement is about more than lifting. It’s about precision, efficiency, and adaptability. A wheel loader material pushing device transforms a loader into a versatile bulk-handling tool, allowing operators to push, level, and clean with speed. At Sibom, our lineup of pushers and blades are engineered to integrate seamlessly with machines from CAT, Bobcat, and Kubota, helping businesses achieve safer and faster workflows.

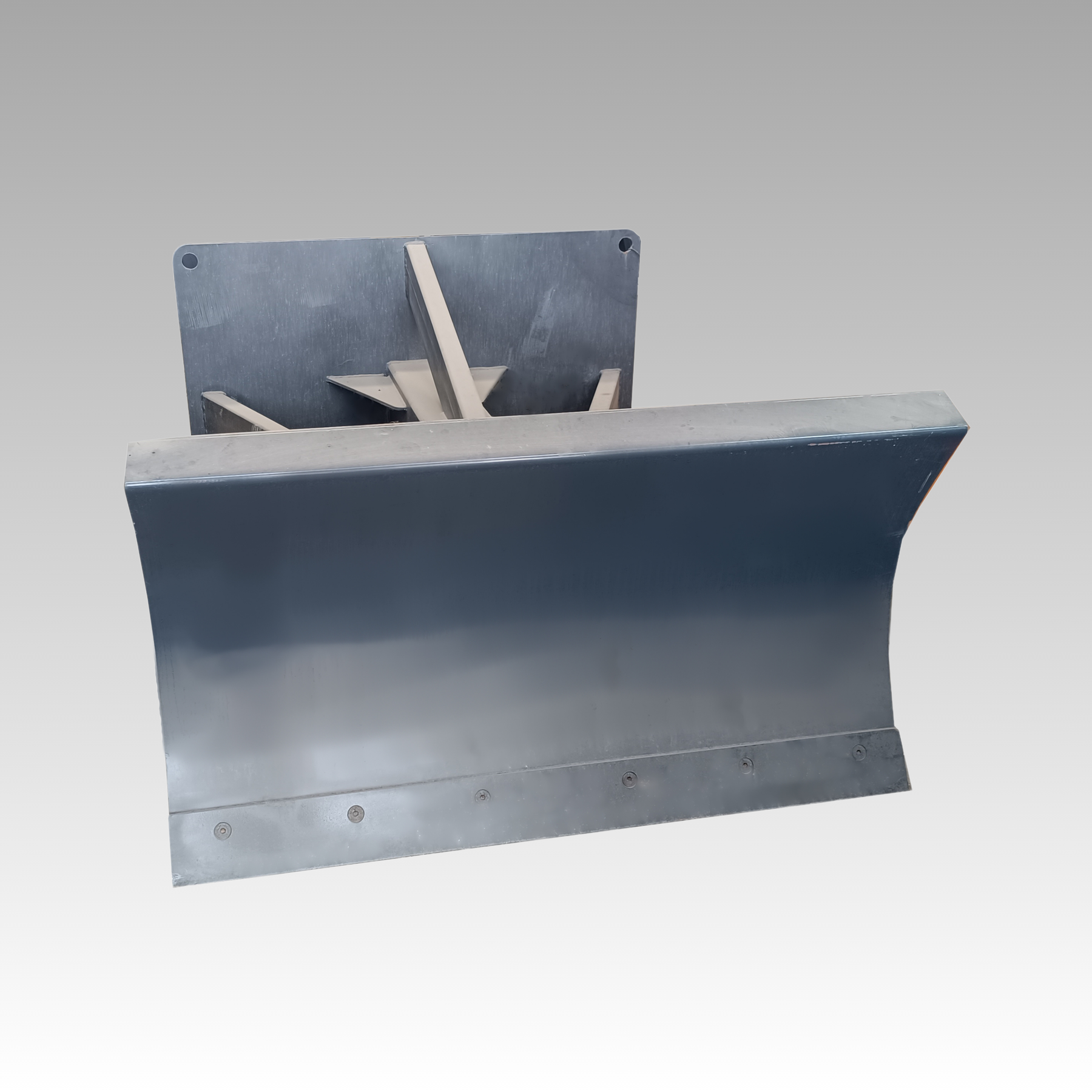

1. Understanding Material Pushers

The concept of a wheel loader material pusher or wheel loader push blade is simple: a strong, mounted blade designed to push or sweep loose materials across a site. But the applications are wide-ranging. For example, in rail operations, the wheel loader freight yard pusher and wheel loader train carriage unloading blade speed up the unloading process, while the wheel loader loose material pusher handles sand, grain, or aggregates effortlessly.

Heavy industries benefit from the wheel loader bulk material pusher, wheel loader yard scraper blade, and wheel loader yard cleaner blade, perfect for maintaining clean and organized yards.

2. Rail and Dock Operations

Rail and port environments demand specialized tools. The wheel loader freight yard push blade, wheel loader railcar unloading blade, and wheel loader railway yard pusher are designed to clear and move bulk goods with minimal downtime.

At docks, the wheel loader dock material pusher and wheel loader dock cleanup blade ensure smooth loading and unloading, while industrial areas benefit from the wheel loader industrial yard pusher and wheel loader stockpile pusher for moving heavy loads.

3. Agriculture, Mining, and Bulk Goods

Agricultural facilities require efficiency and safety. The wheel loader grain push blade, wheel loader coal push blade, wheel loader ore pushing device, and wheel loader iron sand pusher ensure quick handling of bulk feed, fertilizers, or raw materials. Construction and landscaping rely on the wheel loader aggregate push blade, wheel loader soil pushing blade, wheel loader sand pushing device, and wheel loader debris pushing blade to keep sites clear and organized.

For winter and weather-related work, the wheel loader snow pushing device doubles as a cleanup tool for yards and municipal areas.

4. Productivity and Operator Comfort

Efficiency is at the heart of Sibom’s design. Products like the wheel loader productivity push blade, wheel loader labor saving pusher, and wheel loader cost effective push device reduce cycle times and manual effort.

Maintenance is minimized with the wheel loader low maintenance pusher, wheel loader maintenance friendly push blade, and wheel loader energy efficient pusher. For user comfort, the wheel loader operator friendly pusher and wheel loader safe material pusher are engineered to reduce fatigue while keeping safety first.

5. Versatile Applications and Features

From stockpiles to tunnels, Sibom provides solutions:

-

Wheel loader stable push blade and wheel loader precise pushing device for sensitive areas.

-

Wheel loader smooth push blade and wheel loader minimal spillage pusher for clean operations.

-

Wheel loader clean sweep push blade, wheel loader compact push device, and wheel loader narrow space push blade for confined environments like warehouses.

-

Wheel loader confined area pusher and wheel loader tunnel push blade for underground work.

6. Cleaning and Loading Operations

Material handling isn’t always about transport; sometimes it’s about cleaning and clearing. The wheel loader hopper cleanout pusher, wheel loader conveyor feed pusher, and wheel loader silo cleanout blade simplify routine maintenance in plants.

Loading and unloading efficiency improves with the wheel loader hopper unloading blade, wheel loader container unloading pusher, and wheel loader truck loading pusher. For organized transport, the wheel loader transport channel pusher, wheel loader reclamation push blade, and wheel loader waste pushing blade keep materials moving.

7. Heavy-Duty Performance

Job sites demand durability. The wheel loader rubble pushing blade, wheel loader side material pusher, wheel loader front push device, and wheel loader wide push blade handle rugged work.

For standard specifications, Sibom offers the wheel loader 59 inch push blade and wheel loader heavy duty push blade. Wear protection comes with the wheel loader wear resistant push blade, wheel loader replaceable blade pusher, wheel loader bottom blade pusher, and wheel loader front blade pusher.

Customization options like the wheel loader customizable push blade, wheel loader limiting block pusher, and wheel loader collecting bucket push blade provide tailored solutions.

8. Advanced Hydraulic and Quick-Coupler Systems

Time is money. The wheel loader tipping bucket push blade, wheel loader hydraulic push blade, and wheel loader quick attach pusher speed up attachment swaps. Universal coupling options include the wheel loader quick coupler push blade, wheel loader fast install pusher, and wheel loader easy mount push blade, all compatible with CAT, Bobcat, and Kubota.

9. Long-Term Value

Investing in a pusher should mean durability. That’s why Sibom’s wheel loader durable push device, wheel loader robust push blade, wheel loader high strength push blade, and wheel loader long life pushing device are built to last.

Efficiency-driven tools like the wheel loader efficient material pusher, wheel loader pile leveling pusher, wheel loader heap management blade, and wheel loader grading push blade help manage stockpiles and site prep.

Additional attachments such as the wheel loader scraper push blade, wheel loader rake push device, wheel loader flat blade pusher, and wheel loader curved push blade add flexibility.

10. Industry-Specific Uses

Steel and construction industries appreciate the wheel loader steel push blade, wheel loader reinforced push blade, and wheel loader impact resistant pusher for heavy-duty tasks. Maintenance teams like the wheel loader bolt on blade pusher, wheel loader multi purpose push blade, and wheel loader versatile pushing device for varied needs.

For yard upkeep, the wheel loader yard maintenance pusher, wheel loader landscaping push blade, wheel loader snow yard push blade, and wheel loader construction site pusher keep sites neat. Demolition teams rely on the wheel loader demolition debris pusher and wheel loader municipal push blade.

Finally, recycling and commodity handling benefit from the wheel loader cleanup pusher, wheel loader material handling pusher, wheel loader commodity push blade, wheel loader bulk goods pusher, wheel loader reclaim push blade, and wheel loader pile push attachment.

11. Why Choose Sibom?

Sibom’s range of wheel loader push blades and devices redefines material handling. By ensuring compatibility with CAT, Bobcat, and Kubota, operators can enhance their fleet without investing in additional equipment. These attachments offer productivity, safety, and versatility for industries from agriculture to mining.

Whether it’s clearing grain in a silo, leveling coal in a yard, pushing debris on a construction site, or handling cargo at a dock, Sibom delivers solutions that are strong, adaptable, and built to last.

Leave a comment