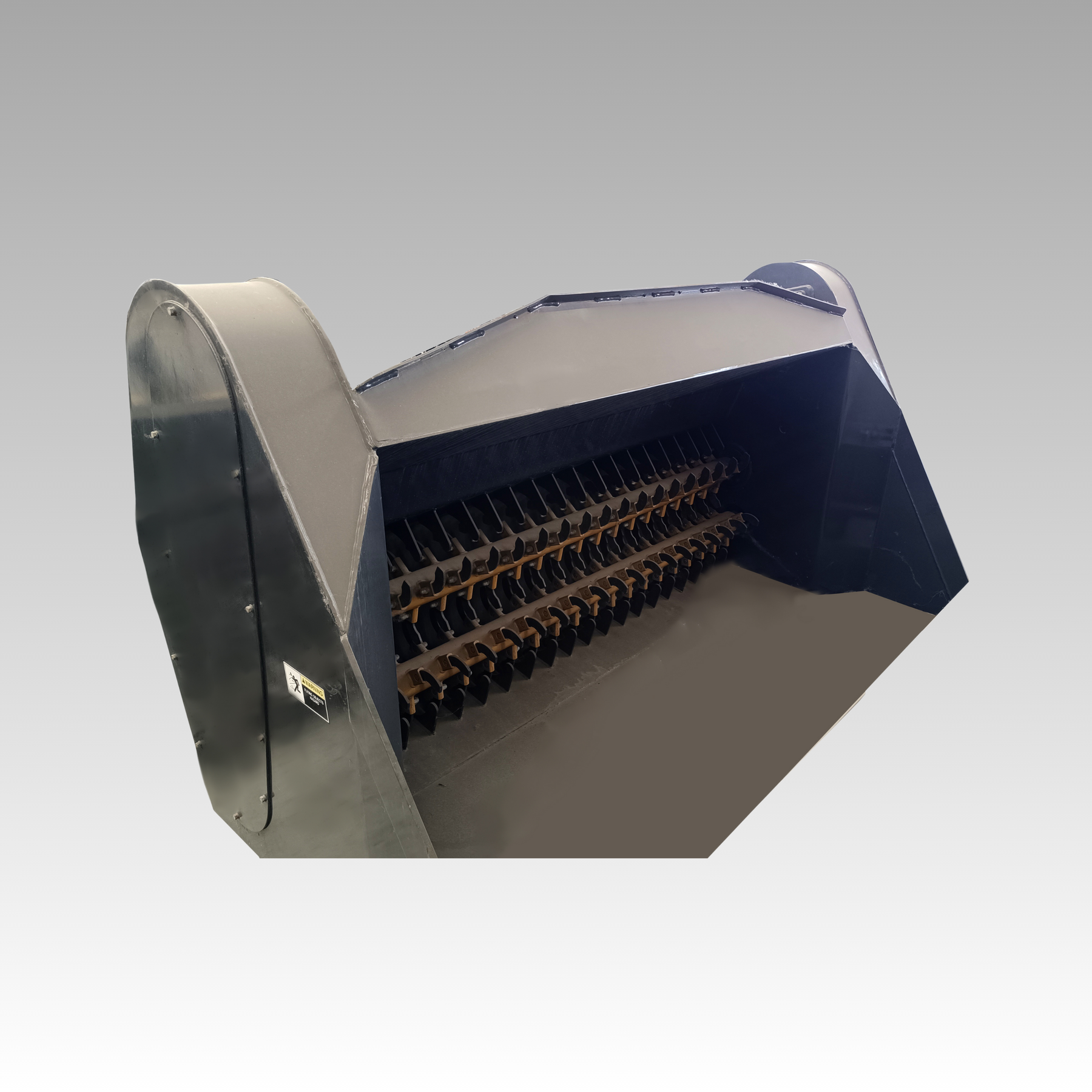

Sibom Wheel Loader Breaking and Screening Buckets – Redefining Material Processing

As job sites evolve and demand more efficiency, contractors and operators are looking for solutions that can handle multiple functions with one machine. A wheel loader breaking and sieving bucket or a wheel loader crushing and screening bucket turns a standard loader into a material processing powerhouse. Sibom’s innovative attachments integrate screening, crushing, sieving, and mixing capabilities into one robust unit, allowing operators to do more while minimizing equipment swaps.

1. Multifunctionality for Modern Job Sites

A wheel loader breaking screening bucket or wheel loader sieving bucket helps streamline operations where materials need to be sorted, sized, or refined before transport. At the same time, the wheel loader crushing bucket and wheel loader screening bucket handle aggregates, topsoil, demolition debris, and recycled products.

Mixing tasks are also simplified with the wheel loader mixing bucket, which enables uniform blending of compost, feed, or fertilizers. The wheel loader crusher screening bucket combines crushing and screening in one motion, maximizing productivity.

2. Power and Efficiency

Performance matters when dealing with tough materials. Sibom offers the wheel loader high power crushing bucket for rock, ore, and rubble, while the wheel loader energy efficient screening bucket reduces fuel use without sacrificing output. Advanced designs like the wheel loader cross rotation bucket, wheel loader double gear bucket, and wheel loader twisted gear bucket improve processing precision.

For demanding crushing, the wheel loader twin gear crushing bucket and wheel loader rapid crushing bucket speed up processing cycles. Meanwhile, the wheel loader efficient sieving bucket and wheel loader uniform mixing bucket maintain consistency across variable material loads.

3. Material-Specific Solutions

Different jobs require specialized attachments. Sibom designs the wheel loader material processing bucket and wheel loader material recycling bucket to meet the needs of waste sorting and construction recycling. For organic operations, the wheel loader compost screening bucket, wheel loader compost mixing bucket, and wheel loader biomass screening bucket handle delicate material with care.

Soil and aggregate work benefit from the wheel loader soil screening bucket, wheel loader soil sieving bucket, wheel loader aggregate screening bucket, wheel loader aggregate crushing bucket, and wheel loader gravel screening bucket.

4. Recycling and Heavy-Duty Applications

For waste management and demolition, the wheel loader construction waste crushing bucket, wheel loader rubble crushing bucket, and wheel loader demolition screening bucket are essential. Recycling centers use the wheel loader recycling screening bucket, wheel loader waste processing bucket, and wheel loader landfill reclamation bucket to recover valuable materials.

Asphalt and roadwork are made easier with the wheel loader asphalt recycling bucket and wheel loader pavement recycling bucket, helping contractors reuse materials efficiently.

5. Agricultural and Biomass Uses

Agriculture demands flexibility. With a wheel loader topsoil screening bucket, wheel loader fertilizer mixing bucket, and wheel loader feed mixing bucket, farms can manage soil, feed, and nutrients in one step. Biomass and forestry applications utilize the wheel loader wood chip screening bucket, wheel loader biomass screening bucket, and wheel loader grain screening bucket.

Energy operations rely on the wheel loader coal screening bucket, wheel loader ore crushing bucket, and wheel loader scrap screening bucket for processing fuel and raw materials.

6. On-Site Recycling

Sibom attachments like the wheel loader triage bucket and wheel loader on site recycling bucket let operators process materials right where they are collected, reducing transport costs and environmental impact. This is enhanced by the wheel loader screening crusher bucket, wheel loader bucket crusher screener, and wheel loader bucket screener, which combine multiple functions.

For mixing, the wheel loader bucket mixer and wheel loader bucket processor streamline blending jobs, while the wheel loader bucket pulverizer and wheel loader bucket grinder handle tougher materials.

7. Advanced Engineering

Sibom invests in smart design:

-

Wheel loader separation bucket, wheel loader sorting bucket – for precise segregation.

-

Wheel loader detachable blade bucket, wheel loader replaceable blade bucket – for easy maintenance.

-

Wheel loader low maintenance screening bucket, wheel loader quick maintenance bucket – reduce downtime.

-

Wheel loader fast processing bucket, wheel loader productivity bucket, wheel loader high throughput bucket – for peak efficiency.

-

Wheel loader low energy bucket, wheel loader environmentally friendly bucket, wheel loader green crushing bucket – eco-conscious performance.

8. Built for Heavy Industry

Sibom builds equipment to last. Options like the wheel loader robust crushing bucket, wheel loader heavy duty screening bucket, and wheel loader durable sieving bucket handle extreme conditions. Operators needing longevity can trust the wheel loader long life breaking bucket, wheel loader industrial crushing bucket, wheel loader mining screening bucket, and wheel loader quarry crushing bucket.

Rock and stone work are handled by the wheel loader rock screening bucket, wheel loader rock crushing bucket, and wheel loader stone sieving bucket, while the wheel loader sand screening bucket manages finer tasks.

9. Integrated Processing Attachments

Sibom offers complete solutions:

-

Wheel loader bucket classifier, wheel loader fine screening bucket, wheel loader coarse screening bucket – for sizing precision.

-

Wheel loader variable output bucket, wheel loader adjustable screening bucket – for custom needs.

-

Wheel loader multi material bucket, wheel loader versatile screening bucket – for mixed loads.

-

Wheel loader combo crushing bucket, wheel loader integrated screening bucket – for all-in-one jobs.

-

Wheel loader inline crushing bucket, wheel loader inline screening bucket – for continuous processing.

Supporting attachments like the wheel loader processing attachment, wheel loader crushing attachment, wheel loader screening attachment, wheel loader sieving attachment, and wheel loader mixing attachment ensure your loader is always ready.

Other specialized tools include the wheel loader material reducer bucket, wheel loader material sorter bucket, wheel loader material sieve bucket, wheel loader screening drum bucket, wheel loader rotating drum bucket, wheel loader horizontal shaft crushing bucket, wheel loader rotor screening bucket, wheel loader blade mixer bucket, and wheel loader twin auger screening bucket.

10. Why Choose Sibom Screening and Crushing Buckets?

Sibom’s engineering focus ensures that every screening and crushing bucket integrates performance, durability, and operator comfort. By making these attachments fully compatible with CAT, Bobcat, and Kubota machines, Sibom provides customers with flexible solutions that fit existing fleets.

These tools improve productivity, reduce waste, and enhance sustainability, making them ideal for industries ranging from construction and mining to agriculture and recycling. Whether you’re processing topsoil, crushing rubble, or screening compost, Sibom’s buckets are built to handle it all.

Leave a comment