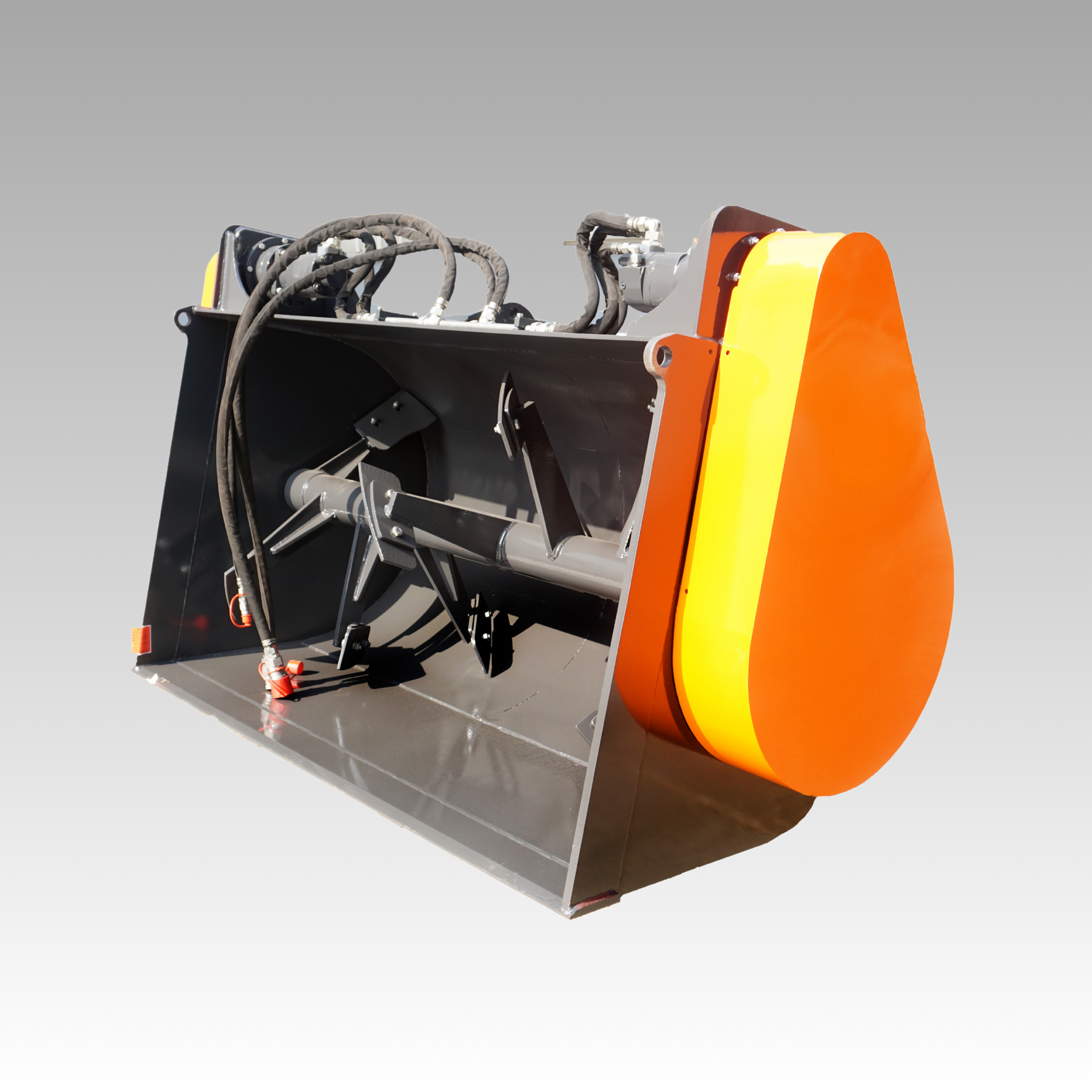

Sibom Wheel Loader Dual Motor Mixing Buckets – Efficient On-Site Mixing Solutions

Modern construction, road maintenance, agriculture, and industrial projects require materials to be mixed quickly and precisely. Traditional mixers are bulky and limit flexibility, but with the right attachment, a wheel loader becomes a powerful mobile mixing station. Sibom’s wheel loader dual motor mixing bucket series offers high-performance blending technology that integrates directly with CAT, Bobcat, and Kubota wheel loaders.

1. Introduction to Mixing Buckets

The wheel loader mixing bucket is designed to prepare and deliver fresh mixes directly where they are needed. Unlike stationary mixers, the wheel loader concrete mixing bucket and wheel loader cement mixing bucket allow operators to transport, mix, and pour materials in one operation.

Advanced options like the wheel loader dual hydraulic motor mixer and wheel loader hydraulic mixer bucket deliver smooth rotation and consistent blending, making them ideal for construction sites, road repairs, and industrial yards.

2. Versatility in Applications

Sibom’s wheel loader mixer attachments can be adapted for countless uses:

-

Wheel loader bucket mixer, wheel loader agitator bucket, wheel loader rotary mixing bucket, and wheel loader stirrer bucket – for standard concrete and mortar.

-

Wheel loader material mixing bucket, wheel loader aggregate mixer bucket, wheel loader sand mixing bucket, wheel loader gravel mixing bucket, and wheel loader stone mixing bucket – for construction aggregates.

-

Wheel loader mortar mixing bucket, wheel loader slurry mixing bucket, and wheel loader screed mixing bucket – for precision flooring and finishing applications.

-

Wheel loader soil stabilizing mixer and wheel loader soil mixing bucket – for agriculture and road foundations.

3. Specialized Concrete and Mortar Solutions

For architectural and specialized projects, the wheel loader colored concrete mixer, wheel loader paving mixer bucket, and wheel loader construction mixer bucket bring flexibility. Contractors working in remote or limited-access jobsites rely on the wheel loader jobsite mixer bucket, wheel loader industrial mixer bucket, wheel loader mining mix bucket, and wheel loader quarry mixer bucket for robust output.

When precision is needed, the wheel loader road repair mixer bucket, wheel loader bridge deck mixer bucket, and wheel loader precast mixer bucket deliver consistent results. The wheel loader shotcrete mixer bucket and wheel loader walkway mixer bucket extend capabilities into spraying and small-scale construction.

4. Agricultural and Industrial Use

Beyond construction, Sibom’s attachments serve farms and processing plants:

-

Wheel loader agriculture mix bucket and wheel loader feed mixing bucket – for livestock nutrition.

-

Wheel loader fertilizer mixing bucket and wheel loader compost mixing bucket – for soil enrichment.

-

Wheel loader resin mixing bucket – for industrial applications.

-

Wheel loader asphalt cold mix bucket and wheel loader slurry seal mixer bucket – for road maintenance.

-

Wheel loader fireproof mortar mixer and wheel loader refractory mixing bucket – for high-temperature materials.

-

Wheel loader grout mixing bucket – for structural repairs.

5. Lightweight and Reinforced Options

Specialized mixes need specialized tools:

-

Wheel loader lightweight concrete mixer, wheel loader fiber reinforced mix bucket, and wheel loader colored mortar mixer – for custom building solutions.

-

Wheel loader material homogenizer bucket – ensuring uniform composition.

-

Wheel loader quick attach mixer bucket, wheel loader ISO coupler mixer bucket, and wheel loader skid coupler mixing bucket – guaranteeing fast compatibility with machines like CAT, Bobcat, and Kubota.

6. Productivity and Speed

Contractors value efficiency. The wheel loader ready mix bucket, wheel loader batch mixing bucket, and wheel loader on-site mixing bucket allow jobs to be completed without hauling pre-mixed loads. High-speed models such as the wheel loader rapid mix bucket, wheel loader high speed mixer bucket, and wheel loader high capacity mixer bucket cut waiting time.

The wheel loader efficient mixing bucket, wheel loader homogeneous mix bucket, and wheel loader anti agglomeration mixer ensure consistent results.

7. Advanced Mixing Technology

Precision mixing requires innovative design:

-

Wheel loader even diffusion mixer, wheel loader cross trajectory mixer, and wheel loader adjustable paddle mixer – for controlled blending.

-

Wheel loader long hole paddle bucket and wheel loader variable stirrer bucket – for flexible materials.

-

Wheel loader replaceable plate bucket, wheel loader wear resistant plate bucket, and wheel loader low friction mixer bucket – for long life.

-

Wheel loader durable mixing bucket, wheel loader robust mixer attachment, and wheel loader high strength mixing bucket – for demanding workloads.

8. On-Site Batch Mixing

With the wheel loader onsite batch mixer, operators prepare materials where needed, eliminating transportation delays. Tools like the wheel loader mixing equipment bucket, wheel loader heavy duty mixer bucket, and wheel loader rugged mixing bucket improve jobsite resilience.

Global compatibility is ensured by the wheel loader euro mount mixer bucket, wheel loader universal mixer bucket, and wheel loader ISO coupler mixer bucket.

9. Operator Safety and Maintenance

Sibom ensures ease of use with the wheel loader easy maintenance mixer, wheel loader low downtime mixer bucket, and wheel loader operator friendly mixer. Safety features in the wheel loader safety mixing bucket protect workers, while the wheel loader productivity mixing bucket and wheel loader labor saving mixer reduce workload.

The wheel loader integrated mixer bucket, wheel loader bucket and mixer combo, and wheel loader mix and load bucket combine mixing and loading, streamlining workflow.

10. Twin Motor and Energy Efficiency

The hallmark of Sibom innovation is the wheel loader cement agitator bucket, wheel loader twin motor agitator bucket, wheel loader dual drive mixer bucket, and wheel loader twin motor stirrer bucket, which provide synchronized, balanced blending.

These energy-efficient tools, such as the wheel loader energy efficient mixer, wheel loader smooth rotation mixer, and wheel loader fast blend bucket, reduce fuel consumption while delivering consistent performance.

11. Long-Term Value

Sibom products, like the wheel loader homogenization mixer, wheel loader concrete batch bucket, and wheel loader mixing solution bucket, are designed for durability and adaptability. Reinforced structures, wear-resistant plates, and ergonomic controls guarantee long service life while minimizing maintenance costs.

12. Why Choose Sibom Mixing Buckets?

Sibom’s dual motor mixing buckets transform CAT, Bobcat, and Kubota wheel loaders into complete mobile mixing plants. Operators can prepare, transport, and pour concrete, mortar, or specialized mixes in one operation. These attachments save time, reduce labor, and ensure consistent, high-quality mixes on every project.

Whether it’s laying concrete on a bridge deck, mixing feed on a farm, or stabilizing soil on a roadbed, Sibom’s mixing attachments offer unmatched versatility, strength, and efficiency.

Leave a comment