Precision Road Surface Solutions: Sibom’s Wheel Loader Manhole Lid Milling Machines for Urban Maintenance

In modern road construction and urban infrastructure management, localized and precise road surface repairs are critical—not just for function, but for safety, drainage, and long-term performance. Among the most common—and most challenging—issues faced by municipal crews and road contractors is the unevenness around manholes, inspection wells, and utility lids. That's where Sibom steps in with its industry-leading wheel loader manhole lid milling machine solutions.

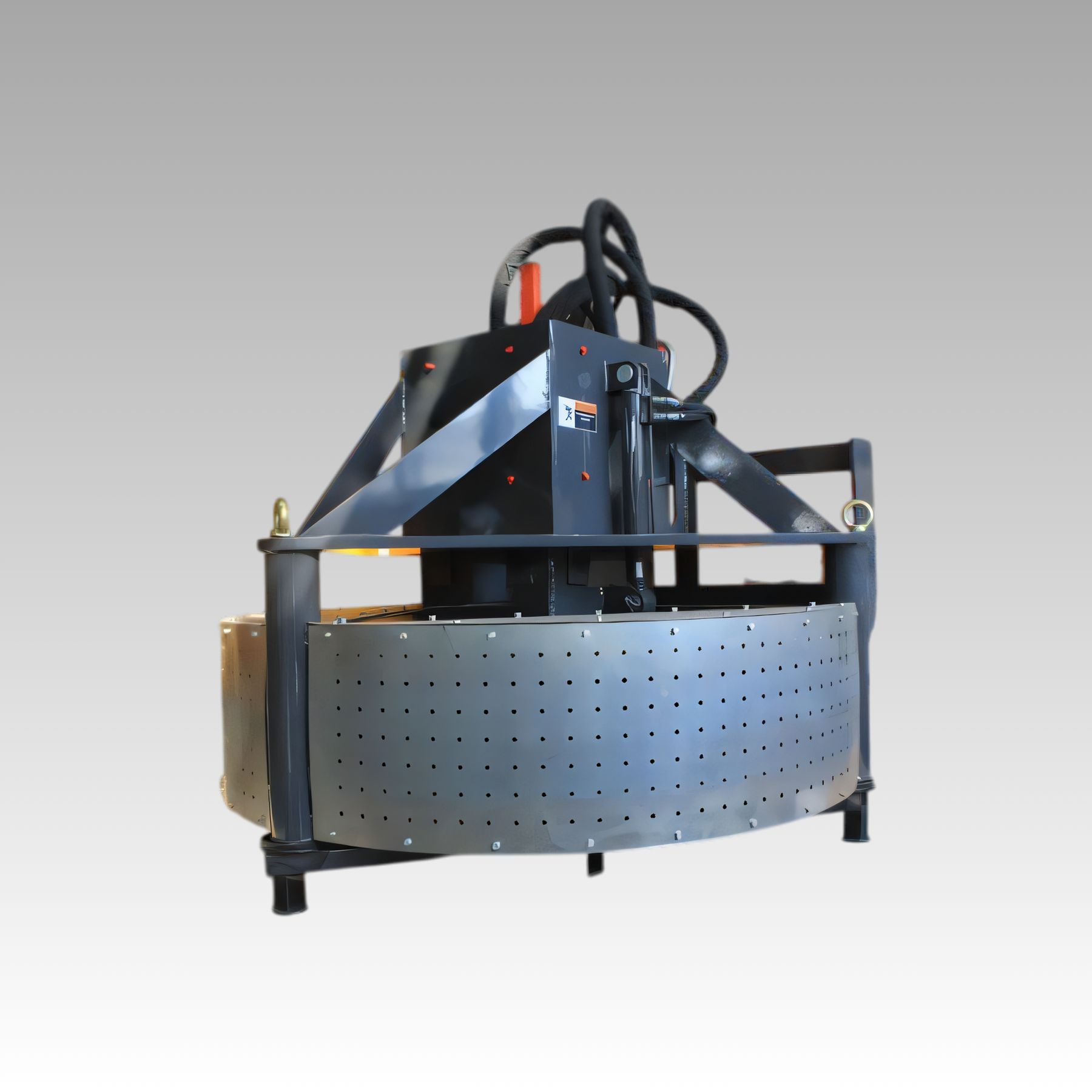

Sibom’s dedicated range of wheel loader well lid milling machine attachments is engineered for high-precision, localized surface removal around sewer lids, storm drains, and utility access points. Designed to mount seamlessly onto mainstream loaders like CAT, Bobcat, and Kubota, our tools bring reliable, professional-grade manhole resurfacing capability to the machines already in your fleet.

Targeted Performance for Urban Infrastructure

Traditional cold planers are oversized and inefficient when it comes to delicate or circular milling tasks. The Sibom wheel loader manhole cover milling machine, also known as the wheel loader well lid cutter or manhole lid cutter, is built for small-area milling, enabling clean, symmetrical ring cuts for manhole seat milling, lid seat refacing, and inspection well milling.

Whether you’re working on a road junction, utility hole, or urban street, our wheel loader manhole repair mill offers pinpoint accuracy and stable depth control. These attachments are optimized for surface corrections around asphalt manhole lids, concrete manhole covers, and even embedded drainage covers or sewer lids.

Engineered for Precision and Durability

At the core of each Sibom attachment is a high precision milling machine head, available with options such as the wheel loader hydraulic milling head, direct drive milling head, or hydraulic oil powered mill. The entire system is engineered to maintain consistent performance, even in demanding conditions like gritty concrete, layered asphalt, or urban traffic surfaces.

Our precision ring cutter and circular groove cutter options ensure the entire manhole seat or lid perimeter is milled evenly. This results in a cleaner repair zone, which improves sealing, eliminates road dips or bumps, and enhances road aesthetics.

With optional adjustable milling blocks, limiting blocks, and seat ring milling heads, Sibom empowers operators to mill precise circular grooves around even the most irregular manhole placements—an essential for proper drainage and long-term structural integrity.

Operator-Friendly and Efficient

Designed with field crews in mind, Sibom’s wheel loader manhole lid miller series is built for easy operation and quick training. These user friendly milling heads are ideal for municipalities or contractors performing repeated resurfacing work.

Key features include:

-

Quick attach milling machine configurations

-

ISO coupler milling attachments

-

Quick connect mill options for fast deployment

-

Easy install milling machines for minimal setup time

-

Compact milling head designs ideal for urban mobility

Operators working on pavement repair, utility lid leveling, or road surface preparation will find the fatigue-reducing operation and ergonomic control design intuitive and efficient—even during long hours.

Enhanced Cooling and Tool Longevity

When working with abrasive surfaces like asphalt and concrete, overheating and tool wear are serious concerns. That’s why Sibom integrates optional water spray mills, water cooled milling machines, and tool cooling systems into its milling solutions.

The efficient tool cooling system ensures that steel plate milling heads and milling drums stay at optimal temperature, even in hot climates or high-friction environments. This dramatically extends the long life of milling tools, reducing downtime and boosting ROI.

Need to switch cutters quickly? Our quick replace cutter system and maintenance milling device allow you to refresh your rig with minimal labor or delay.

Ideal for Asphalt and Concrete Applications

Sibom’s wheel loader asphalt manhole mill and concrete manhole mill attachments allow contractors to address uneven manhole rings during road maintenance or resurfacing. This specialized machinery eliminates the need for jackhammers, manual chiseling, or imprecise cold planer passes.

Our asphalt patch milling, pothole ring milling, and surface leveling mill options are optimized to correct grade issues while leaving surrounding pavement intact. This is critical for urban inspection well mills and utility hole resurfacing, where city regulations demand minimal disturbance outside the cut ring.

Even complex applications like road smoothness correction, micro milling, or defect repair benefit from the smooth surface mill design and seamless milling machine construction of Sibom attachments.

Built for Tough Environments

Durability is a core focus of every Sibom product. Each robust milling machine features a reinforced frame, vibration-damping components, and industrial-grade drive systems.

The heavy duty milling attachment and rugged milling machine configurations offer powerful cutting action while maintaining jobsite safety and long tool life.

Key durability features include:

-

Steel cutting components

-

Hydraulic torque arms

-

Ring groove stability

-

Reinforced housing for surface contact

Whether you're milling for a manhole lifting mill or utility lid milling machine, your crew will be equipped for maximum uptime with minimal maintenance.

Versatility Across Municipal, Industrial, and Construction Sites

Sibom’s solutions shine in a wide range of environments:

-

Urban road milling machine: Perfect for city resurfacing teams

-

Municipal road junction mills: Handles repetitive manhole projects efficiently

-

Utility lid maintenance: Ideal for sewer, drainage, and gas access points

-

Parking lot repairs: Fixes cover alignment without repaving the entire surface

-

Airport and port surfaces: Localized correction for surface integrity

-

Construction dust zones: Useful in phased resurfacing or demolition areas

Whether you're milling for a road manhole repair, manhole rehabilitation, or pavement manhole mill, our tools offer consistent results with minimal disruption.

Seamless Road Maintenance at Scale

Municipalities and contractors benefit from Sibom’s road maintenance mills through:

-

Reduced traffic disruption from localized milling

-

Cleaner, more professional manhole seating

-

Elimination of uneven cover transitions

-

Improved ride quality for drivers and cyclists

-

Enhanced drainage and reduced long-term maintenance

With our wheel loader manhole edge cutter and surface preparation mill, agencies can meet surface tolerance regulations while reducing repair timelines and rework costs.

Why Choose Sibom?

Because when it comes to milling around manholes, not all attachments are created equal.

Sibom combines:

-

Precision ring cutting technology

-

Durable, jobsite-ready components

-

Compatibility with CAT, Bobcat, Kubota, and more

-

Ease of operation, even for new operators

-

Industry-grade performance in a compact, loader-mounted package

We design every localized patch mill, specialized manhole mill, and resurfacing cutter with your real-world challenges in mind. From the first cut to the final surface match, Sibom helps you restore road integrity and extend infrastructure lifespan—without overextending your equipment or budget.

Conclusion: The Right Cut for the Right Cover

If your road crews are still using oversized equipment or manual tools for manhole and well lid repairs, it’s time to upgrade to the precision and efficiency of Sibom’s wheel loader manhole cover milling machines. Designed for loader-mounted agility and engineered for pinpoint accuracy, these tools are the new standard for urban and industrial road maintenance.

Backed by seamless compatibility with CAT, Bobcat, Kubota, and other major loader brands, Sibom’s attachments empower your fleet to handle small-area road repairs with confidence, cleanliness, and speed.

Leave a comment